Shanghai

Sister of the ship Pekin

Contents

History

July 1873. Delivered to C.N.Co. for deployment on the lower Yangtse river. Initially the vessel had a black hull, but changed to the grey Yangtse livery. For the machinery details see the "Pekin". All cargo was man-handled through the side hatches (ports).

1880. A.Holt's Ocean Steamship Co. "Achilles" when fully loaded with tea, went aground at Hankow. The "Shanghai" towed her off and took her to Singapore. The loyalty by the Swires to Holts was shown as no salvage rights claimed, only the towage costs involved.

1890. On the voyage from Shanghai to Hankow the "Shanghai" caught fire and was beached and gutted 6 miles below the Mud River Fort near Chekiang. Over 200 deck passengers were lost when they jumped over the side into the river with their belongings as they were unable to swim. The ship was salvaged but not repaired.

1894. Converted to a hulk for use by CNCo.

1935. Hulk sold.

Service

Events / Stories

"Achilles Machinery."

The interesting feature of the "Achilles" was the engine, a Vertical Steam Compound Tandem Single Crank Engine, designed by Phillip Holt in conjunction with Scotts & the Greenock Foundry, and built by the Greenock Foundry Company. The engine and boilers etc. is described in "Two centuries of Shipbuilding By The Scotts At Greenock" published in 1906.

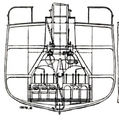

The cylinders were:- high pressure, 30 inches dia.: low pressure, 62 inches dia., with 4ft. 4 inches stroke, arranged vertically in tandem fashion, with the low pressure on the top. There were two connecting-rods, but a common crosshead for the tandem cylinders, and a common crankpin. The crankshaft was 13 1/2 inches in diameter, with a bearing 30 inches long at the aft end of the bedplate, which took the propeller thrust. The propeller was three bladed, 17ft. diameter, with 26ft 6in. pitch. When running at 46 rpm., the piston speed was 400 ft. per minute. To ensure smooth working with the single crank, a heavy flywheel was fitted, and the pump levers carried a massive weight to help balance the weight of pistons and rods.

The condenser had 420 tubes 1 1/2 inches dia., giving a cooling surface of 1,375 square ft. The tubes were arranged in three nests, the water circulating through the top one first and the bottom one last. The circulating pump, instead of forcing water through the tubes, as was usual in such a case, sucked from the condenser and discharged directly overboard. There were:- one air pump of 24 inch in dia., one circulating pump of 24 inch dia., two feed pumps 4 3/4 inch dia. and one bilge pump 7 inch in dia. all the pumps were single acting with a 17 inch stroke. The diameters of the principal pipes were :- main steam 7 1/2 inch dia., steam to low pressure cylinder 12 inch dia., circulating inlet 10 inch dia., and discharge 12 inch dia., air-pump discharge 10 inch dia., main feed pipe 3 3/4 inch dia., and waste steam pipes, two at 6 inch dia. See Images section for engine arrangement.

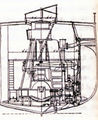

The two boilers were double-ended of the locomotive type, with wet bottomed furnaces. The centre was cylindrical, but the ends were rectangular with semi-cylindrical tops. The total weight, without water being 78 tons. Each boiler had a long receiver passing through the uptake to dry the steam. On the receiver was a deadweight safety-valve 6 1/4 inch dia. to suit a working pressure of 60lb per square inch. The grate surface was 112 square feet, and the total heating surface 4,506 square feet, there being 328 iron tubes of 4 inch dia. See images section for boiler arrangement.

In 1876 the engine was replaced by a two cylinder compound engine, where each piston was connected through a crosshead to a connecting rod to its own crank on the crankshaft.

Only three of this type of engine were ever built, the other two being installed in the sister ships Ajax and Agememnon all of which were later replaced by the two cylinder compound engine.

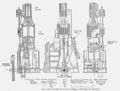

A proposed design for a larger two cylinder compound engine is shown in the images section, which was intended to be installed in a further three vessels. This engine was never built.

A further feature of these three vessels was that the propeller was abaft of the rudder, which worked in an aperture in the "deadwood" corresponding to that for the propeller in modern ships. This arrangement is the reverse of today's practice, and proved to be unsatisfactory, as the response when maneuvering proved to be quite sluggish. The relative position of the propeller is discussed in the book about Isambard K. Brunel's "Great Britain". "The Iron Ship" by Ewan Corbett. A further consideration being that no stern frame was required, instead the substitution in the main hold of two pillars in place of the usual numerous stanchions, a three feet frame spacing and the disuse of cement on the ships bottom inside the ballast tanks. It should be remembered that these ships were constructed of iron and not steel.